NIKON

BOEING

AEROSPACE TECHNOLOGY CENTER

WEBER

KUKA

ABB

AMRC

STAUBLI

DYZE

EVO 3D

EVO 3D

WASP

CEAD

MASSIVE DIMENSION

MELTIO

FANUC

YASKAWA

COMAU

What Ai Build Does

Fully automated toolpath generation for industrial additive manufacturing

The entire 3D printing process – monitored, controlled, measured and optimized.

Our goal is to enable Additive Manufacturing to scale and realize its global potential.

Through advanced automation, slow and error-prone manufacturing becomes fast, predictable and repeatable.

Increased 3D printing capability through one simple UI that manages even the most advanced toolpaths across all 3D printers in any location.

Design compromises due to 3D printing limitations?

Advanced, Segmented, Conformal, Spiral, 45 Degrees and Non-Planar toolpaths, with automated Adaptive Speed Control.

Real World Applications

AiSync is trusted across many verticals including automotive, aerospace, marine, energy and construction. Below you can see some of the real world examples of how AiSync is used in manufacturing.

Building The Factory Of The Future, Sustainably.

Shorter supply chains, faster access to product, reduced carbon footprint.

AiSync is a cloud based platform allowing you to manufacture parts either locally or remotely.

With real-time connectivity, you can view, simulate, control and monitor machines in the next room, or next continent.

We have repurposed over 10 tones of recycled materials to date, reducing greenhouse gas emissions by approximately 70%.

Software

AiSync

Simple, Automated Efficiency.

AiSync accelerates and automates the creation of even the most advanced, multi-axis toolpaths via a single, intuitive UI.

Our intelligent AM platform replaces manual coding with visual programming, to completely simplify toolpath generation.

A digital twin provides full visual build simulation and collision avoidance. Also equipped with powerful reporting and analytics, the entire 3D printing process is optimized and fully repeatable.

Software

AiSync PRO

Adding to AiSync capability, our AiSync PRO platform utilizes deep machine integration to stream manufacturing instructions directly to your machine and provide direct, real-time control over the entire additive manufacturing process.

AiSync PRO

Fleet Management

Manage, control and monitor your organization’s fleet of 3D printers through securely encrypted protocols from any device.

Multiple user groups can easily interact with multiple machines in different locations for effortless collaboration and scalable production.

AiSync PRO

Automated Quality Control

With our sensor fusion technology and AI algorithms, AiSync PRO analyzes the real time process data from your hardware to send automatic notifications about production quality and minimize waste.

AiSync PRO

AUTOMATIC REPORTS

AiSync PRO provides an interactive report for each of your production jobs including insights about production quality and large amounts of process data.

Everything is recorded and made accessible to your organization for full traceability through customizable dashboards and integrations into existing MES / ERP systems.

Robot and Gantry system simulation

Solved kinematics for ABB, KUKA, FANUC, STAUBLI, COMAU Robots and cartesian systems.

multi axis parametric toolpaths

Fully parametric reusable toolpaths, nonplanar, multiplanar, segmented slicing strategies.

Various 3d model supports

Supports typical design file formats (OBJ, STEP, STL, 3MF, GLTF).

Collision Detection

Collision detection specific to your hardware.

Analytics

Real time monitoring and notification of your system sensors.

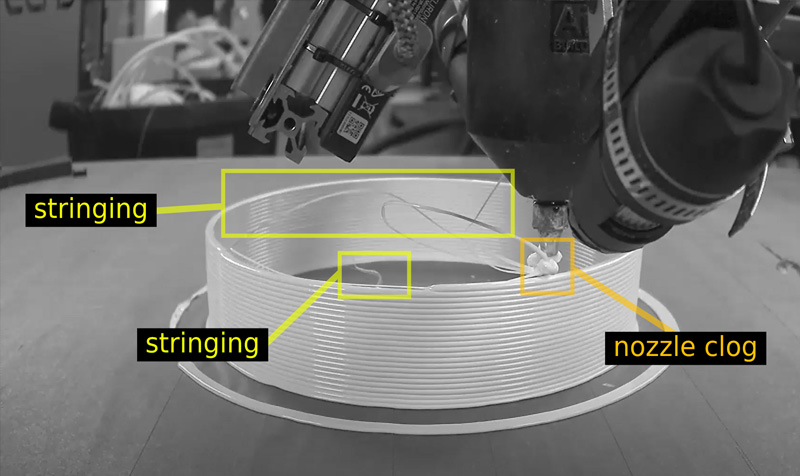

Error Detection

AI machine learning error detection through years of gathering data.

AiLab

We recognize the requirements to successfully scale industrial 3D printing globally, which is why in our London AiLab, we test, all day every day, sharing experience and outcomes. This rich data set we share in our Knowledge Centre with our clients and partners. Our team of AM engineers conduct material characterizing, machine integrations and testing, the results are inputted into our additive manufacturing platform ensuring full automation and repeatable, successful outcomes.

WEBER

EVO 3D

DYZE

WASP

CEAD

MASSIVE DIMENSION

MELTIO

Material Characterization

Polymers, Metals, Concrete

We’re working hard with our Material partners and Hardware vendors to hard code material properties inside our AiSync Platform.

From Advanced Polymers such as Dulthram, PEEK, ABS, RPETG, CarbonP to high performance engineering alloys such as Aluminium, Titanium and Nickel to automatically adjust the toolpath generation for the specific material properties.

AM Expertise – that is 100% our focus

Smart people, efficient processes, amazing technology. Ai Build is a technology partner, not a technology vendor, providing agile development not corporate inflexibility. We provide an open approach to our technology roadmap along with tested, robust technology and personalized onboarding and support.

Our Partners

Connecting, Collaborating & Innovating

We are building an AM community with the express intention of improving AM outcomes for clients and supporting partner growth. Our global partner network includes robotics systems, gantry systems, extruders, material partners and complete system vendors and our customer centric collaboration drives innovation symbiotically.

About Ai Build

AI Build is a fast-growing London based Software-as-a-Service company, that is disrupting the Additive Manufacturing industry on a global scale. Our clients are tier 1 companies operating in the Aerospace, Automotive, Construction, Marine and Energy verticals. Our unique software enables them to fully automate the additive manufacturing process from plan to print, radically improving speed, quality, scalability, and application range, across the entire enterprise. We integrate and partner with a growing network of hardware manufacturers, and we are backed by first class investors.

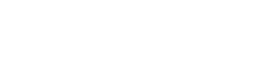

Meet the Founders

Ai Build is founded by Daghan Cam (CEO) and Michail Desyllas (COO) in 2015.

Daghan and Michail met as architects whilst leading major projects for Zaha Hadid, where they utilised their deep experience in geometric problem solving.

The also enjoy a common passion for Additive Manufacturing, which combined with their geometric expertise led to the conclusion that there was a significant AM capability gap.

For large format AM to truly scale, “trial and error” manual process, long build time and failed build rates needed to be addressed.

Advanced automation and a data driven approach would be the key to broadening application range and operational efficiency, making AM mainstream in the factory of the future.

AiBuild was founded out of that experience and perspective. AiSync, our AM software platform is built to deliver just that, at enterprise scale.

With a growing network of clients and partners around the globe, Ai Build continues innovating rapidly to bring the founders bold vision for autonomous additive factories of the future into life.

SOCIAL NEWS!

CNC Robotics & MELTIO

We welcomed Michael Mead from 3DGBIRE to our site today 🔧

Mike lent us a helping hand with the testing of our freshly integrated Meltio system...

WE ARE HIRING!

Join our dynamic team! We’ve currently got 16 open positions for a range of talented individuals in commercial and technical roles including; Product Manager, Customer Success, UI/UX Engineer, Robotics Engineer and Software Engineers.

2019 DUBAI Pavillion

How long do you think it took to print 128 parts? Just a few days with AiSync AM software.

Completed in 2019 in collaboration with MEAN* Middle East Architecture Network we upcycled 30,000 discarded water bottles from Reflow to produce the Deciduous...

DEFECT DEDECTION

We’ve got Luke Rogers in our AiLab today talking about our work on defect detection! So far we have captured some where in the region of 10,000,000 printing defects which have been fed to our machine learning model...

Meet our Frontend Engineer!

Maryan has been critical in developing some of our most recent AiSync capabilities, including our Recommendation Engine and optimisation of our UI.

With over 9 years of experience in the industry...

MELTIO Multiplanar Toolpaths

You might be familiar with this multiplanar geometry, printed support free, in polymers - we are also applying our advanced AiSync tool path capabilities to metals.

DYZE & KUKA

Want to be one of the first to see AMCell_small? A fully integrated additive manufacturing production cell teaming AiSync AM software with KUKA robot and DYZE DESIGN extruder.

WEIR Minerals

We are delighted to announce that together with Weir Minerals and MTC - Manufacturing Technology Centre, we have been awarded Department for Energy Security and Net Zero (ESNZ) funding as part of the Industrial Energy Efficiency Accelerator phase 4.

AMCell

Want to see the first AMCell_ ? We’ll be showcasing this fully integrated, turnkey additive manufacturing solution at Talking Industry live with KUKA in just over two weeks time!

ARUP Engineers

Our Senior Creative Engineer Berin Nur Kocabaş participated in the Arup Data-Driven Design & Fabrication Event in #london last week. The event showcased how technology can push design and engineering boundaries.

The TCT Group

We are delighted AiSync AM software is one of the finalists for The TCT Group Software award...

Airbus Defence and Space

How do we optimise AiSync AM software for defence and space?

With highly critical applications comes engineering challenges. In the defence and space industry, end-use applications like this antenna tower need to be highly geometrically accurate with uniform material properties across the entire geometry...

Thermal Simulation

AiSync - spot the difference….!

Same geometry, hardware, print bed and material, and day - radically different results. The left video shows a cone geometry printed using LFAM without AiSync...

WEBER Additive

We had the pleasure of welcoming WEBER additive, one of our valued partners to the AiLab this week! It was a great opportunity to catch up with their team and showcase some of the innovative applications our engineers are using Weber extruders teamed with AiSync AM software for.

Daedalus Pavilion

In 2016 we showcased Daedalus Pavilion, a 3D printed architectural installation produced with AiSync AM software for Europe’s first NVIDIA GPU Technology Conference in Amsterdam, NL.

Fronius and KUKA!

AiSync’s deep integration with KUKA hardware enables us to really push the R&D and Production boundaries of AM engineering. This example shows AiSync, KUKA robot arm with external axis and WAAM Fronius systems enabling challenging designs like this to be reliably printed.

Lehmann&Voss&Co. KG

New high temperature material tested and validated for AiSync AM software!

Lehmann&Voss&Co. KG Luvocom 1100 GF 30 NAT, glass filled PES successfully printed with large-format robotic additive manufacturing. Initially developed for injection moulding, this high temperature material was printed with minimal shrinkage at 365°C in a non temperature controlled environment.

DLR Institute of Structures and Design

DLR new approach for complex composite structures uses AiSync AM software to marry the flexibility of additive manufacturing with Automated Fibre Placement laminate (AFP).

Talking Industry

Are you going to the Talking Industry Industries Live event on 25th April?

You won't want to miss Luke Rogers discussing the exponential possibilities of automated additive manufacturing at 2pm.

CNC Robotics

It’s the perfect way to end the week seeing one of the latest integrations for a client!

This one features two KUKA Robots, two Güdel Group linear tracks teamed with Massive Dimension extruders.

3d printing TOOLING BOARD

Taking just 15 minutes, this 1 metre polyurethane tooling part was printed using AiSync AM software with robotic large-format additive manufacturing, resulting in 60% reduction of raw material needed.

MELTIO & 3DGBIRE

Exciting day at the AiLab!

Our trusted partners 3DGBIRE came to film the Meltio engine and showcase the complex capabilities achieved when robotic arm metal printing is teamed with AiSync additive manufacturing...

ATI HUB

Don't miss our Head of R&D Guy Brown speaking about LFAM for aerospace at the Innovator Showcase at 3pm!

You can also come by our booth to see our large format additive manufacturing prints in ULTEM, Meltio stainless steel ...

Additive Manufacturing Strategies

Our CEO Daghan Cam will be speaking next week at Additive Manufacturing Strategies on the Automation, AM and the Factory of the Future panel in #newyork

Daghan will be touching on automation and Ai and the impact these will have on how additive manufacturing....

Printing with ULTEM

ULTEM successfully printed with large format robotic arm additive manufacturing!

A fully certified additive manufacturing material for aerospace components, ULTEM outperforms comparable thermoplastics when it comes to resisting creep ....

KUKA AMCell_Small

Very exciting to see the first AMCell_Small

Fully integrated with AiSync software, its amazing to collaborate with industry titans KUKA to shape the future of AM...

Our Partners CEAD

Our team visited CEAD Group, one of our trusted hardware partners last week! It was great to catch up in person with the CEAD team and check out their amazing facility...

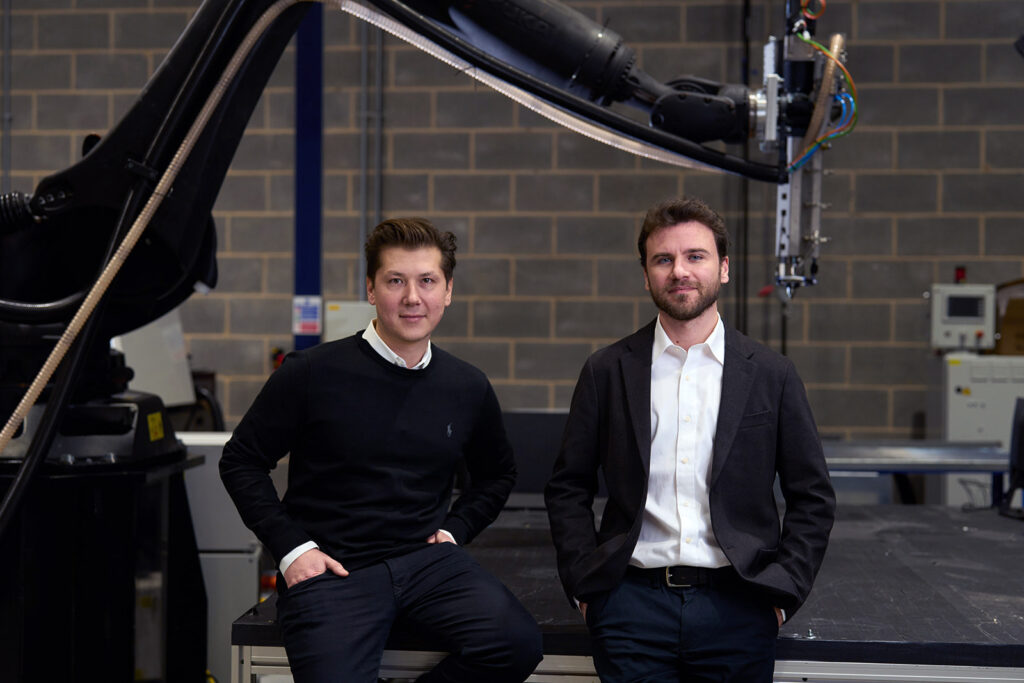

Talk to AiSync

We’ve been working on something game-changing.

Talk to AiSync uses natural language to fully automate the generation of production ready 3D printing files....

3DPOD PODCAST

Did you catch Daghan Cam sitting down with 3DPrint.com Joris Peels and Max Bogue to discuss AiSync software for robotic arm additive manufacturing?

Daghan discusses the way companies approach 3D printing and streamlining production like never before. Be sure to check out this podcast episode to learn more about our game-changing software for AM!

2023 Predictions

What will impact the course of Additive Manufacturing in 2023?

We see 2 mega trends…

1. Generative AI: more automation

2. Open-architecture platforms: more partnerships